Category : Healthcare

The CSSD (central sterile supply department) also called sterile processing department is an integrated place in hospitals which is the service responsible for receiving, storing, processing distributing and controlling the professional supplies and equipment for all user unit of hospital for the care and safety of patient under strict quality control”.

It is an important facility of hospital that supplies sterile instruments and materials for dressing and procedures carried out in ward and other departments of hospital.

CSSD has a great role in reducing Hospital Acquired Infection (HAI)

CSSD (Central Sterile Supply Department) @ JSS Hospital, Mysuru Salient features:-

- Biggest CSSD in Mysuru 718sq meter

- Situated in basement of JSS hospital

- 24*7 sterile services

- First CSSD to have plasma sterilizer in whole of Mysore

- Total manpower 21 people

- Receiving and Supplying sets and dressing materials to wards and ICUs on door step

- Committed to provide quality care and safety for patient in cost effective manner

- Only CSSD in Mysuru to get ACE accreditation from CAHO

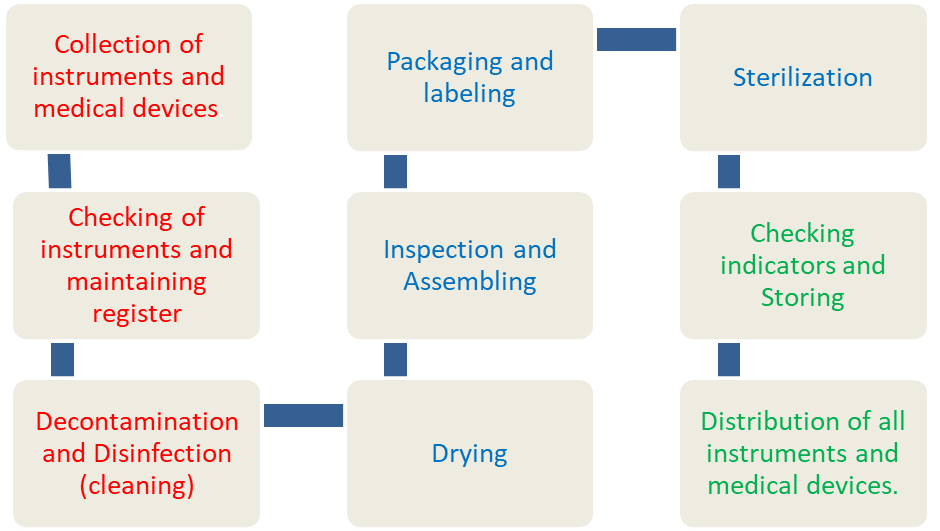

Work Flow in CSSD is Uni-directional flow-

Layout of CSSD @ JSS Hospital, Mysuru

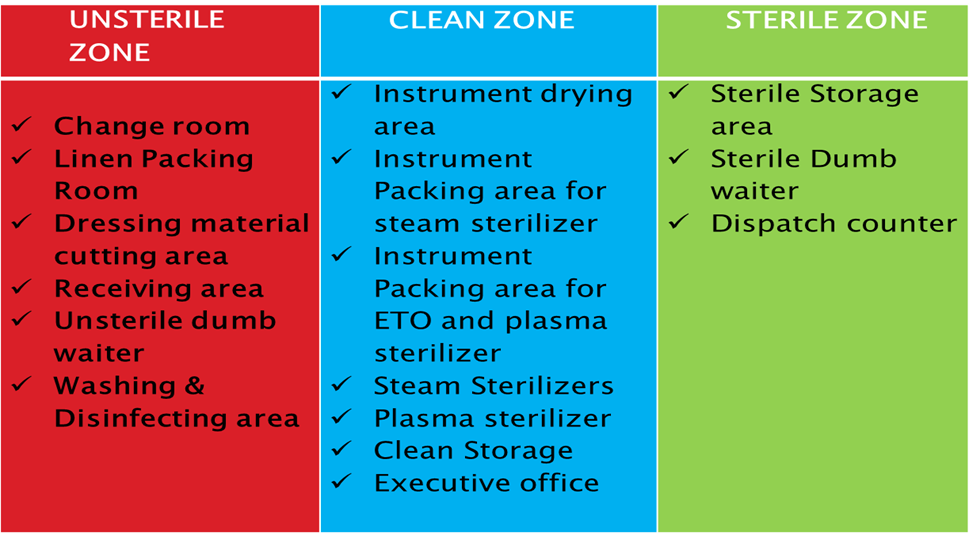

CSSD ZONES:-

Types of sterilization

Steam sterilization

steam under pressure is the cost- effective method of sterilization,

- Steam sterilization two type gravity cycle and prevaccum cycle.

- We can sterilize all heat resistant’s surgical packages like OT, ICU, Ward sets and dressing materials.

Advantages

- Non toxic

- Cycle easy to control & monitor

- In expensive

Disadvantages

- Potential for burns.

- Cant sterilize Heat sensitives items

ETO Sterilization

Items like cardiac catheters are heat sensitive and therefore cannot be sterilized by steam. Such items are sterilized by ethylene oxide (ETO) gas sterilization. The ETO is an expansive and toxic gas. it is absolutely necessary to ensure that these items are made free of gas molecules before using them on a patient. This is achieved by subjecting the items to forced ventilation. The entire cycle may take about 8- 12 hrs.

Advantages

- Very effective at killing microorganisms.

- Penetrates medical packing and many plastics.

- Cycle easy to control and monitor.

Disadvantages

- Lengthy cycle.

- Potential hazard to patient and staff.

Plasma sterilization

Low-Temperature Hydrogen Peroxide Gas Plasma (LTHPGP) has a number of advantages compared to established sterilization technologies. These include a short cycle and long cycle sterilization, low temperature and humidity, no aeration requirement, no toxic chemical residues or environmental impact

Advantages

- Safe for the environment and health care worker it leaves no toxic residuals.

- Fast- cycle time is 58 to 72 mints and no aeration necessary.

- Used for heat and sensitive surgical items.

Disadvantages

- Cellulose (paper), linen and liquids cannot be processed.

- Devices restrictions based on lumen internal diameter.

Other equipment used are

Supporting Departments

For more information on CSSD and its role in Hospital, Kindly contact Dept of CSSD, JSS Hospital, Mysuru.